Nanofibers

What are nanofibers?

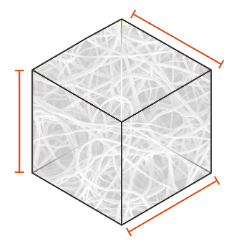

They have a huge specific surface

The 1 m² nanofiber membrane has the same surface size as a football field.

Small pore size

Pores between nanofibers have dimensions of about 20-100 nanometers. So bacteria, viruses, allergens don't go through them. But it can release air molecules.

Variable diameter

We can control the diameter of the fibers according to how we need to apply them.

Nanofibers are fibers whose diameter ranges from several nanometers to several hundred nanometers. One nanometer is 0.000000001 meters or 10 ا9 meters and is not

visible to the eye without the use of an optical apparatus. For comparison, a human hair has a diameter of

about 75,000 nanometers.

Scientists were able to produce the first nanofibers as early as the first half of the 20th century, and therefore this is not new in the scientific community, but in the past only a very limited amount of nanofibers could be produced with the technologies of its time and was therefore not suitable for mass-widespread industrial applications. It was only at the turn of the 20th and 21st centuries that the technological maturity of nanofiber production reached such an extent that nanofibers began to be produced in large quantities, opening up new possibilities for industry.

How are they made?

Nanofibers are produced from various natural polymers, such as cellulose, keratin, collagen or synthetic polymers such as PLA, polyurethane PU, PHBV and many others. Each of these materials gives nanofibers its unique properties.

There are many ways in which nanofibers, both for experimental and industrial use, can be produced. Among the most widely used methods of nanofiber production is used:

What is electrospinning?

Elektrospinning is a popular method of nanofiber production, which uses several tens of kV in high voltage production.

In 1964, British scientist Geoffrey Ingram Talyor examined fluid solutions and their behavior when exposed to high voltages. Taylor scooped the solution into the needle and watched as a drop on the tip of the needle exposed to high stress behaved. The drop changed shape with increasing tension until it reached the shape of a cone, and when the stress reached a critical boundary, a thread burst out of the tip of the cone. This phenomenon was named after its discoverer and is therefore known as the Taylor Cone. In the case of solutions, the fibre continues to break down into small particles in the electric field (a phenomenon called electrospraying), in the case of liquid polymers, the fibre does not break down into small particles, but stretches.

This phenomenon is the basis of electrospinning. The polymer fiber, which thus arises from the tip of the cone, begins to stretch in the electric field and thus narrow until the fiber narrows so much that it reaches the nanodimensions. This thread then lands on the collection plate, where it can continue to be worked with. An important skill in the production of nanofibers by electrospinning method is the control of electrical voltage and its effect on the polymer solution and this depends on many factors including the parameters of the production machine.

Nanofibers

Use of nanofibers

Filter membranes

Membranes made by nanofibers can reach smaller pore dimensions and therefore filter even very small particles. At the same time, nanofiber membranes can achieve higher porousness.

Wound bandages

With the help of nanofibers it is possible to create suitable fabrics that have small enough pores to prevent most bacteria from getting through them and at the same time to release air well,

Tissue Engineering

In tissue engineering, nanofibers represent an important role in the construction of "scuffold" for tissue cells.

How nanofibers protect

Nanofibers

Use of nanofibers

It is important to note that the fact that products contain nanofibers does not automatically mean that filtration occurs in the highest filter class. It is precisely the density of nanofibers and the size of the pores that determine the filter quality of the product. Therefore, it is important to pay attention to the filtration certification of the product. If the product is not certified, we recommend that you avoid these products because their filter quality may be so low that they have not passed the certification tests.

EN149 is a European standard that sets the minimum quality of respirators and masks that cover half the face. This standard sets minimum requirements for the ness of the protective equipment as well as the parameters of the FFP categories. During the coronavirus pandemic we could hear many times inflected FFP quality masks and respirators. FFP stands for "filtering facepiece" and is divided into three categories, the lowest filter category is 1 and the highest is category 3. In the US there is a different standardization and the equivalent of FFP is N. Below we can see a comparison of FFP and N standard, the percentage rate is the minimum requirement of capture of all particles 0.3μm and greater.

FFP1

At least 80%

FFP2

At least 94%

N95

At least 95%

N99 & FFP3

At least 99%

N100

At least 99.7%