N-Roll

Product line introduction

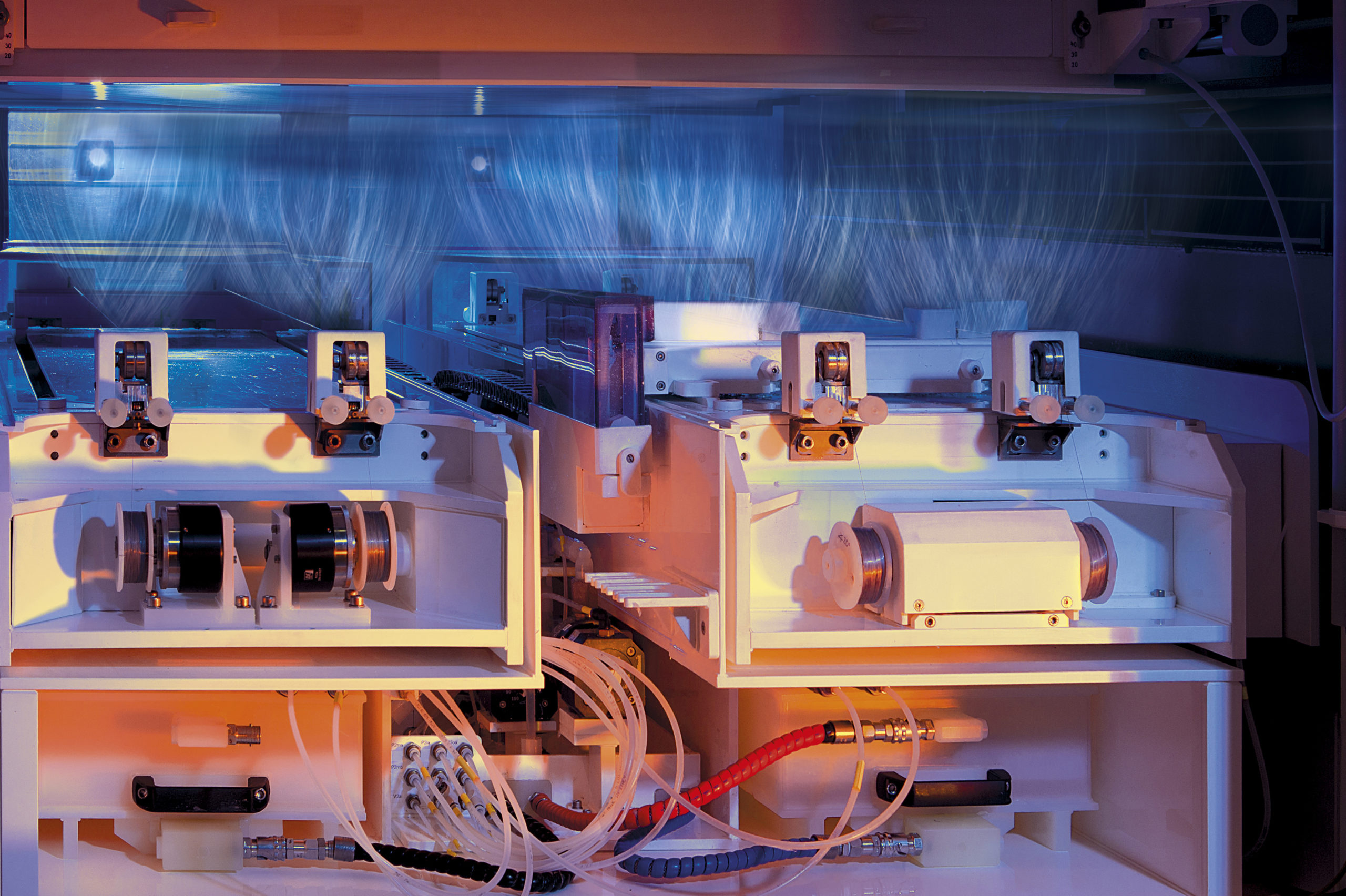

NAFIGATE Park has developed and manufactures nanofibrous composite

media suitable for face masks and respirators. The N-composite roll consists

of a laminated four-layer material with a PVDF nanofiber membrane, in

some versions also enhanced with Ag+ ions built into the fibers of the

nonwoven supporting layer.

We offer N-composite roll in four classes, according to filter efficiency, optimized for the production of medical protective masks (masks) class I+II, IIR and OOPP (respirators) filtration class FFP2 and FFP3.

We offer each filtration class in two versions:

Antimicrobial

with ag+ ions that prevent bacterial growth, and thus are optimal for repeteadly used products.

Basic

without Ag+ ions, ideal for disposable PPE or

medical protective masks

Technical parameters

| Parameter | Unit | Value | FFP2 Requirements according to EN149 |

|---|---|---|---|

| Surface weight | (g/m2) | 67 ± 1 | ON |

| Mean value of nanofiber diameter | (nm) | 100 ± 20 | ON |

| Filter efficiency for particles 278.8-322 nm | (%) @ 95 l/min | > 96,0 | ≥ 94,0 |

| Filter efficiency for particles 94.7-117.6nm nm | (%) @ 95 l/min | > 90,8 | not required |

| Initial penetration of the NaCl aerosol | (%) @ 95 l/min | ON | < 6,0 |

| Initial penetration of paraffin oil | (%) @ 95 l/min | < 1,9 | < 6,0 |

| Initial pressure gradient | (Pa) @ 30 l/min | < 35 | < 70 (vdechovací odpor) |

| Initial pressure gradient | (Pa) @ 30 l/min | < 120 | < 240 (vdechovací odpor) |

| Initial pressure gradient | (Pa) @ 30 l/min | < 150 | < 240 (vdechovací odpor) |

| Parameter | Unit | Value | FFP3 Requirements according to EN149 |

|---|---|---|---|

| Surface weight | (g/m2) | 67 ± 1 | ON |

| Mean value of nanofiber diameter | (nm) | 100 ± 20 | ON |

| Filter efficiency for particles 278.8-399.5 nm | (%) @ 95 l/min | > 99,1 | ≥ 99,0 |

| Filter efficiency for particles 94.7-117.6nm nm | (%) @ 95 l/min | > 94,8 | not required |

| Initial penetration of the NaCl aerosol | (%) @ 95 l/min | ON | < 1,0 |

| Initial penetration of paraffin oil | (%) @ 95 l/min | < 0,5 | < 1,0 |

| Initial pressure gradient | (Pa) @ 30 l/min | < 52 | < 100 (vdechovací odpor) |

| Initial pressure gradient | (Pa) @ 95 l/min | < 194 | < 300 (vdechovací odpor) |

| Initial pressure gradient | (Pa) @ 160 l/min | < 198 | < 300 (vdechovací odpor) |

The full technical sheet can be downloaded here.

N-Mask

Case study

Laminated multilayer material is a key part of N-mask nanofiber masks from nafigo manufacturer. Developed material with PVDF nanofiber membrane and built-in Ag+ ions in the microfiber structure of the carrier layer of non-dodd fabric is designed for the production of reusable surgical masks. The material significantly reduces the likelihood of viruses and bacteria passing into a person's respiratory tract.

The use of material in the production of reusable surgical masks is only one example of how our membranes can be used.

The inner filter consists of a four-inch composite. The new-fold membrane is protected by lamination, thanks to which there is no damage – if the product is handled and worn correctly. The materials used are comfortable, non-wrinkled and quick-drying.

N-mask can be disinfected with denatured ethanol and hand washed without detergents. The filter efficiency of the mask remains very high even after several washing cycles. Other cleaning options include heating in the oven and irradiation with a germicidal UV lamp.

N-Mask is designed and hand-made by professionals in the Czech Republic. The top layer can be printed according to a customer's imagination. It is also possible to choose from several options of fastening – so the product is comfortable for every user.