Products

Product offer for our customers

Custom production

The 1.6m wide industrial lines and 20 years of experience in electrospinning allows us to manufacture custom nanofiber products to meet customer needs and meet the requirements of a variety of filtration applications such as HVAC, gas turbine air intake, industrial dust collection, synthetic HEPA filtration, cabin filters, engine intake, as well as other customer specified applications where nanofibers can be used.

Contractual development

Our long-standing know-how, in-house R&D centre and testing capability enable us to develop new nanofibre products exclusively according to the requirements and needs of our customers, from a wide range of polymers to meet the needs of the market and to meet the most demanding requirements for nanofibre media (also outside the filtration sector).

N-composite roll

A range of fully developed, tested and EN 149, Niosh 42CFR84 and EN 14683 certified multi-layer nanofibre materials that are used by manufacturers of surgical face masks (Class II and IIR) and respirators (Class FFP2 and N95) worldwide. New: Now also available in a biodegradable version that is environmentally friendly and reduces waste.

Nanocleaner

A nanofibre composite designed to filter the air in windows or doors, creating a barrier that prevents the smallest harmful particles such as smog, allergens, bacteria, viruses, dust and PM2.5 from entering the room while allowing fresh air to pass through. By reducing heat transfer, Nanocleaner also contributes to reducing energy consumption in buildings.

Technology

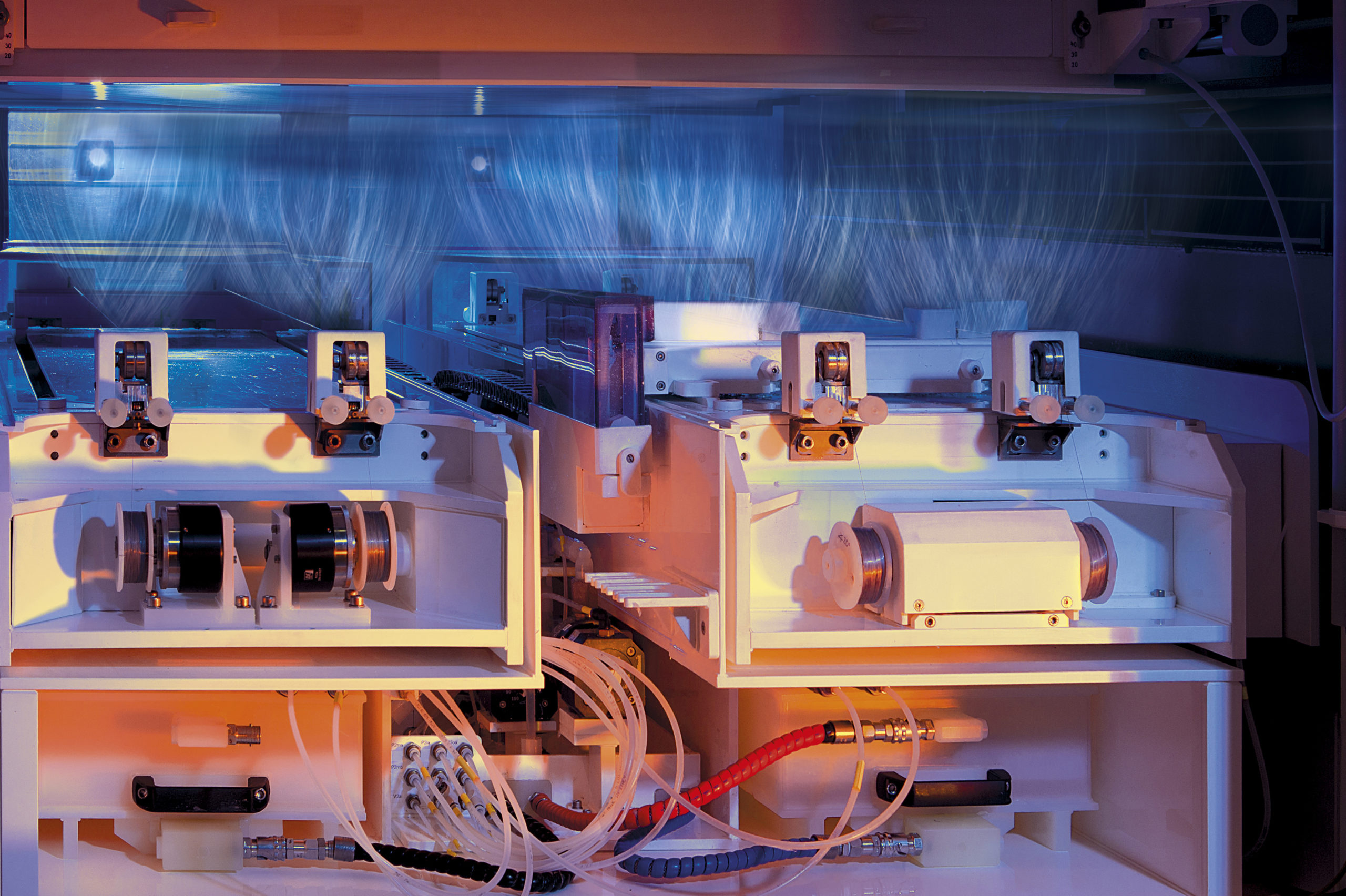

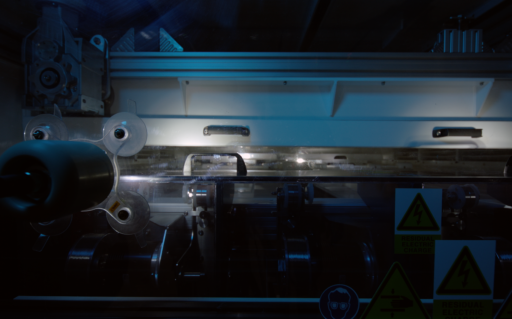

The latest generation of Nanospider™ technology

Nanospider™ is designed to produce nanofibers from a range of polymers deposited on conductive and non-conductive substrates. NAFIGATE Park not only has laboratory facilities to enable nanofibre research and development, but also a 0.5m wide small batch production line and 1.6m wide industrial high capacity lines.

01

Development & Testing

All our products will go through a wide range of tests and optimizations in our development center at the beginning.

02

Production

Production takes place in specially adapted premises for maximum quality of nanofibers.

03

Quality control

A sophisticated quality control system ensures that only the best products reach our customers.

ABOUT US

The story of our company and our values

Our story

NAFIGATE park – the first plant for the production of nanofibers – is being created at the former textile factory Feigl & Widrich – a cultural monument in the village of Andělská Hora. This is a monument with a strong historical story. It is the first nanofigate corporation production plant with its own R&D center.

Our values

Maximum long-term quality

Complete service under one roof

Technology helps people

We work with the best

PARTNERS

Partners we work with

We base ourselves on working with the best and building long-term relationships. Our customers are demanding and motivate us to be the best in the industry.

Product catalog